We have all the important manufacturing processes at our disposal, such as CNC turning, CNC milling, HSC milling, wire and die-sinking EDM, round and flat grinding and of course 5-axis milling. Simultaneous processing is not a foreign word for us, but part of our daily business.

Do you have a machining problem? We’re sure to have the solution for you.

We process parts of up to 4.000 kg in weight and 2.400 x 1.100 x 900 mm in size on 3 axes, as well as parts with 1.200 x 1.200 x 800 mm from all 5 sides. 5-axis simultaneous machining of

components of 1.100 mm diameter and 1.600 kg weight is possible. Our integrated shuttle

tables and large tool changers with up to 120 places in the machining centres make the

economic machining of series possible.

components of 1.100 mm diameter and 1.600 kg weight is possible. Our integrated shuttle

tables and large tool changers with up to 120 places in the machining centres make the

economic machining of series possible.

Additive manufacturing

-

HP Jet Fusion 580 Color

Designation Characteristics Printer series 580 Technology HP Multi Jet Fusion Effective construction volume 332 x 190 x 248 mm Printhead resolution 1.200 dpi Layer thickness 0,08 mm -

Renishaw AM400 HT

Designation Characteristics Construction year 2016 Build Chamber 234 x 234 x 186 mm Laserpower 400 Watt Platform heating 495°C -

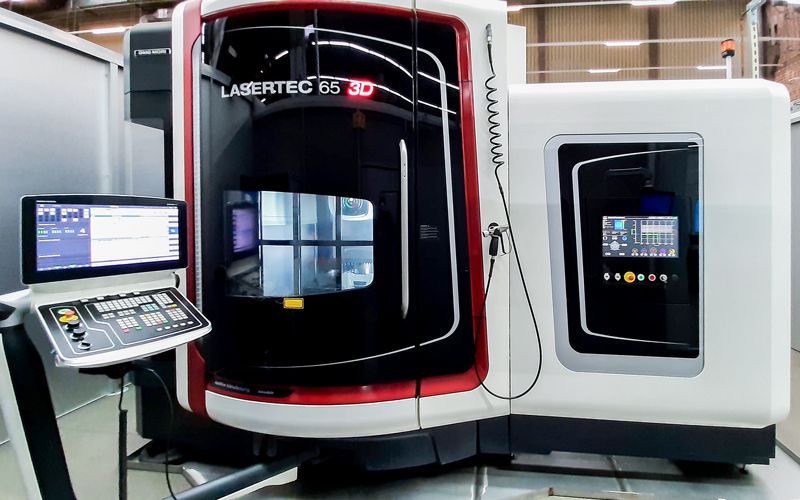

DMG Lasertec 65

Designation Characteristics Construction year 2016 max. Workpiece weight 600 kg max. Workpiece size 735 x 650 x 560 mm Number of tools 30 max. rotation speed 18.000/min Laser 3000W Laser

5-Axis-Milling

-

POSmill H2200U

Designation Characteristics Construction year 2022 max. Workpiece weight 2.500 kg max. Workpiece size 2.200 x 1.400 x 1.000 mm max. interference circle 5-axis 1.900 mm Number of tools 90 max. rotation speed 18.000/min Internal coolant supply Yes -

DMG HSC105 linear

Designation Characteristics Construction year 2012 max. Workpiece weight 800 kg max. Workpiece size 3x 100 x 800 x 500 mm max. Workpiece size 5x D900 x 500 mm Number of tools 60 max. Drehzahl 28.000/min Internal coolant supply Yes Rotary table diameter 950 mm -

DMG HSC75 linear

Designation Characteristics Construction year 2012 max. Workpiece weight 800 kg max. Workpiece size 3x 800 x 600 x 500 mm max. Workpiece size 5x D650 x 500 mm Number of tools 30 max. rotation speed 28.000/min Internal coolant supply Yes Rotary table diameter 750 mm -

Mikron HPM1350U

Designation Characteristics Construction year 2008 max. Workpiece weight 1.600 kg max. Workpiece size 1.350 x 1.150 x 700 mm Number of tools 96 max. rotation speed 24.000/min Internal coolant supply Yes Rotary table diameter 1.100 mm -

Mikron HPM1150U

Designation Characteristics Construction year 2006 max. Workpiece weight 1.100 kg max. Workpiece size 1.000 x 1.150 x 700 mm Number of tools 46 max. rotation speed 15.000/min Internal coolant supply Yes Rotary table diameter 1.000 mm -

Kekeisen UBF2500

Designation Characteristics Construction year 2003 - completely overhauled 2016 max. Workpiece weight 6.000 kg max. Workpiece size 2.500 x 1.200 x 1.000 mm max. rotation speed 6.000/min Internal coolant supply Yes Rotary table diameter 1.200 mm

3-Axis-Milling

-

DMG DMU85 Monoblock

Designation Characteristics Construction year 2011 - completely overhauled 2021 max. Workpiece weight 2.000 kg max. Workpiece sizetd> 935 x 850 x 650 mm Number of tools 30 max. rotation speed 10.000/min Internal coolant supply Yes -

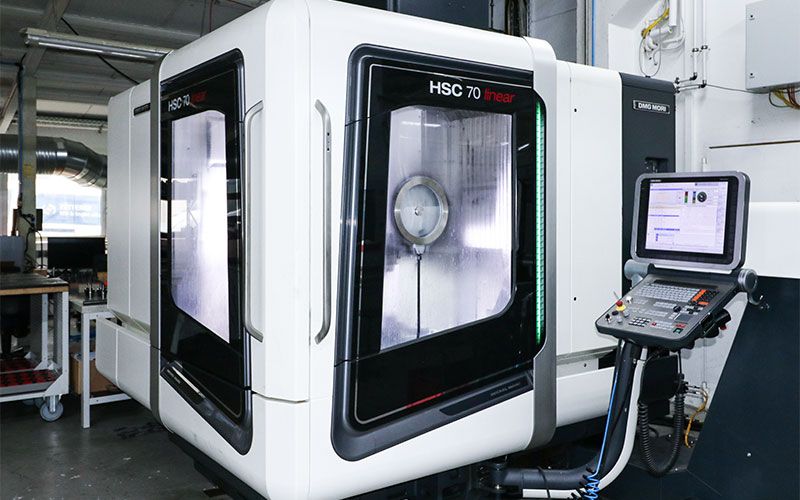

DMG HSC70 linear

Designation Characteristics Construction year 2017 max. Workpiece weight 800 kg max. Workpiece size 800 x 600 x 500 mm Number of tools 60 max. rotation speed 28.000/min Internal coolant supply Yes -

Huron K2X10

Designation Characteristics Construction year 2013 max. Workpiece weight 1.000 kg max. Workpiece size 1.000 x 800 x 500 mm Number of tools 30 max. rotation speed 18.000/min Internal coolant supply Yes -

PosMill 1100

Designation Characteristics Construction year 2016 max. Workpiece weight 1.000 kg max. Workpiece size 1.100 x 800 x 500 mm Number of tools 60 max. rotation speed 12.000/min Internal coolant supply Yes -

PosMill 2050

Designation Characteristics Construction year 2016 max. Workpiece weight 3.000 kg max. Workpiece size 2.050 x 1.150 x 700 mm Number of tools 60 max. rotation speed 10.000/min Internal coolant supply Yes -

PosMill 2050 HSC

Designation Characteristics Construction year 2016 max. Workpiece weight 3.000 kg max. Workpiece size 2.050 x 1.150 x 700 mm Number of tools 50 max. rotation speed 18.000/min Internal coolant supply Yes

Erosion technology

-

GF AC 6050 TW

Designation Characteristics Construction year 2010 max. Workpiece weight 800 kg max. Workpiece size 1.260 x 690 x 360 mm -

GF AC Form 3000

Designation Characteristics Construction year 2010 max. Workpiece weight 2.000 kg max. Workpiece size 1.280 x 1.040 x 450 mm -

GFMS CUT400

Designation Characteristics Construction year 2013 max. Workpiece weight 3.000 kg max. Workpiece size 1.300 x 1.000 x 510 mm -

GFMS CUT400

Designation Characteristics Construction year 2016 max. Workpiece weight 3.000 kg max. Workpiece size 1.300 x 1.000 x 510 mm -

GF AC Form 2000

Designation Characteristics Construction year 2008 max. Workpiece weight 800 kg max. Workpiece size 600 x 400 x 300 mm Number of tools 60

CNC Turning

-

Gildemeister CTX310 eco

Designation Characteristics max. turning length 450 mm max. turning diameter 200 mm Bar capacity 51 mm max. rotation speed 5.000/min + 12-station turret with driven tools

-

CTX510 eco

Designation Characteristics max. turning length 1.000 mm max. turning diameter 320 mm Bar capacity 90 mm max. rotation speed 3.250/min + 12-station turret with driven tools

CNC Measurement Technology

-

EROWA measuring machine CMM Qi

Measuring machine for quality measurement and workpiece and electrode pre-setting. -

GOM

Highly accurate and fast 3D measuring technology for quality control in the production process. -

3D Measurement Technology

In combination with a modern 3D coordinate measuring machine with the Renishaw SP 25 scanning module, we achieve the most accurate inspection results. On request, you will receive a detailed measurement and inspection report for each manufactured part. -

Wave Maschine

Reliable measurement of turned parts with the highest precision, directly in production.

Spotting

-

Spotting press BV30E-R

Designation Characteristics Construction year 2006 max. Workpiece weight 7.000 kg max. Workpiece size 3x 1.500 x 1.000 x 1.000 mm

Microblasting

-

Peenmatic 950 ZID

Designation Characteristics Usable space 940 x 750 x 540 mm After the production of tools, unwanted soiling and surface roughness are caused by erosive or mechanical preparation processes. These flaws can prove to be uneconomical in the production process. The tried-and-tested micro-blasting finishing process can compensate for this effect in the long term - for target-oriented, cost-conscious manufacturing.

Toolmanagement

Toolmanagement

Z-TOOLS

All modern manufacturing is dependent on a large number of well-organised tools. Constant availability and low storage costs are the focus of economically responsible considerations. We use Z-TOOLS to manage our production tools. This tool management system orders tools automatically according to consumption. It also supports work preparation and CAM programming with regard to selecting the right tools. This ensures a smooth manufacturing process - the production process is never unnecessarily interrupted.