Additive

Manufacturing

Manufacturing

Additive

Manufacturing

SLM

The SLM powder bed process enables mold tempering close to the contour. Component quality and cycle time in injection molding production are optimized. ZETTERER takes over the additive manufacturing and the required subsequent finishing completely as an extended workbench.

- Complex components with function integration

- Internal, near-contour tempering channels

- Economical production

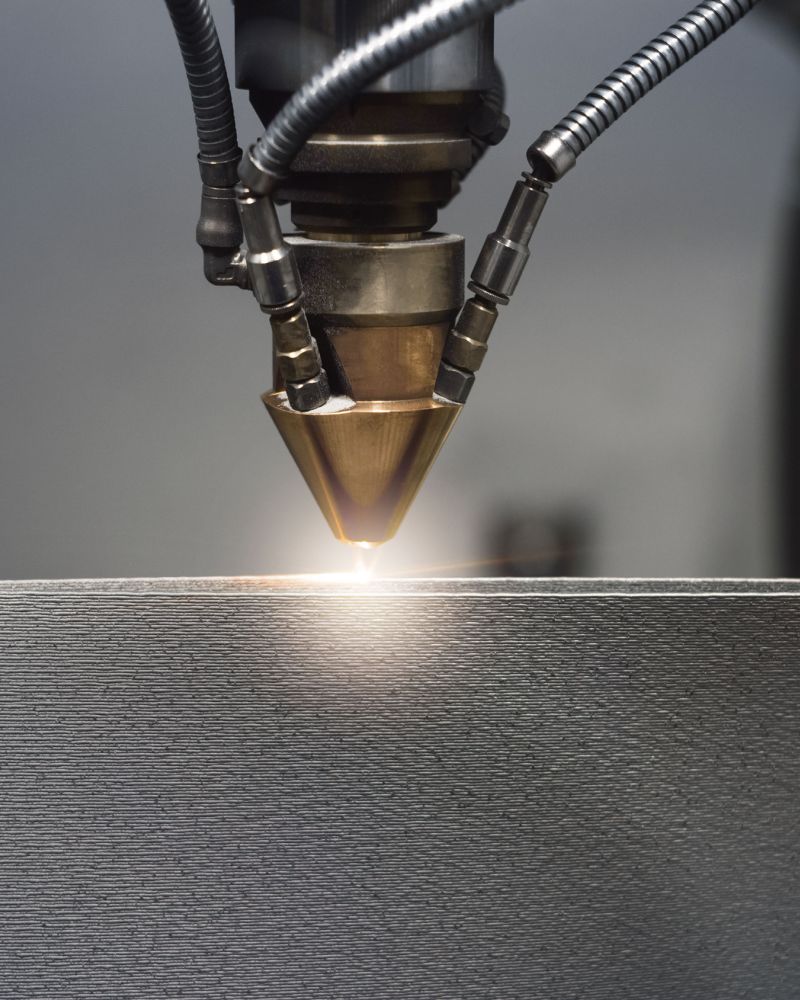

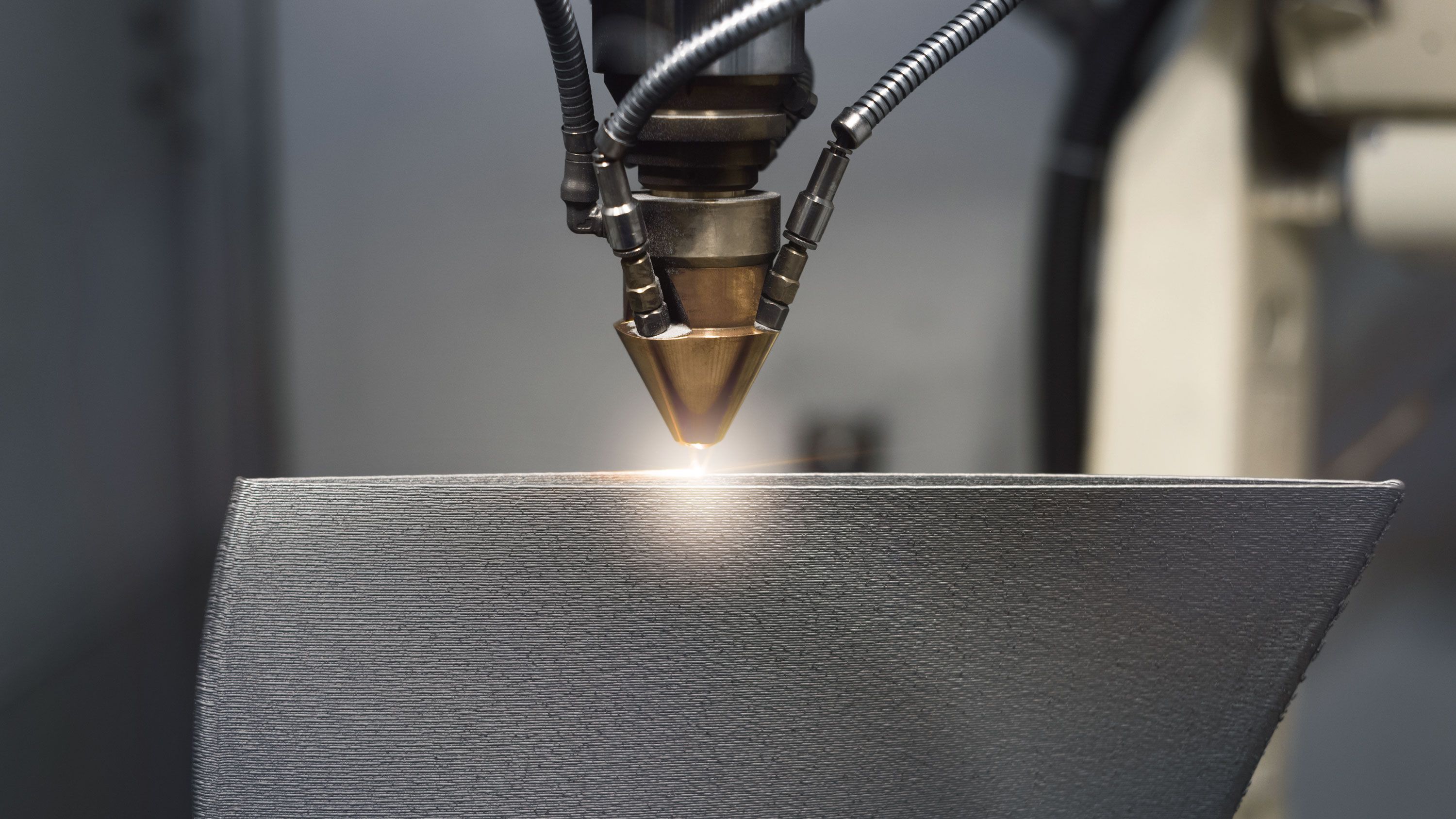

DED

Additive manufacturing by Directed Energy Deposition (DED) with coaxial powder nozzle, combined with 5-axis milling and turning. This enables ZETTERER to quickly and cost-effectively repair existing components through hybrid manufacturing.

- Perfect for component repair

- High printing speed

- High quality metal parts

MJF

Multi Jet Fusion (MJF) is a powder-based 3D printing process that produces precise 3D parts with a high density and low porosity. Perfect for producing prototypes with functional and mechanical properties at high build speeds.

- High build speed

- Perfect for prototyping

- Components achieve high density and low porosity

Contact Person

Telephone: 09171 83999-10

Mail:This email address is being protected from spambots. You need JavaScript enabled to view it.

Contact Person:

Alexander Zetterer

Mail:

Contact Person:

Alexander Zetterer

Downloads