Engineering

Practice oriented consulting

For more than 55 years, ZETTERER has been offering expert advice that is characterized by a combination of practice and experience. In any case, you and your customers will benefit from our sustainable optimization of processes in day-to-day business.

- ZETTERER understands production processes down to the last detail

- Even before the start of construction, we are happy to support you with your projects

- Optimally advised. Economically manufactured. Perfectly manufactured.

CAD/CAM

With Catia V5, ProEngineer, Siemens PLM, Solidworks and Autodesk Inventor, ZETTERER processes native CAD data without conversion. By testing technical details through a simulation of moving parts in the CAD system, we minimize your costs.

- ZETTERER works with the system of your choice

Simulation (die casting)

Casting simulation for die casting is established throughout the industry. By using simulations in the pre-development phase, errors in the design of die castings can be avoided at an early stage. ZETTERER offers this service as part of manufacturing inquiries.

The five steps of casting simulation:

- 3D geometry modeling

- Networking

- Determination of process parameters

- Calculation

- Result evaluation

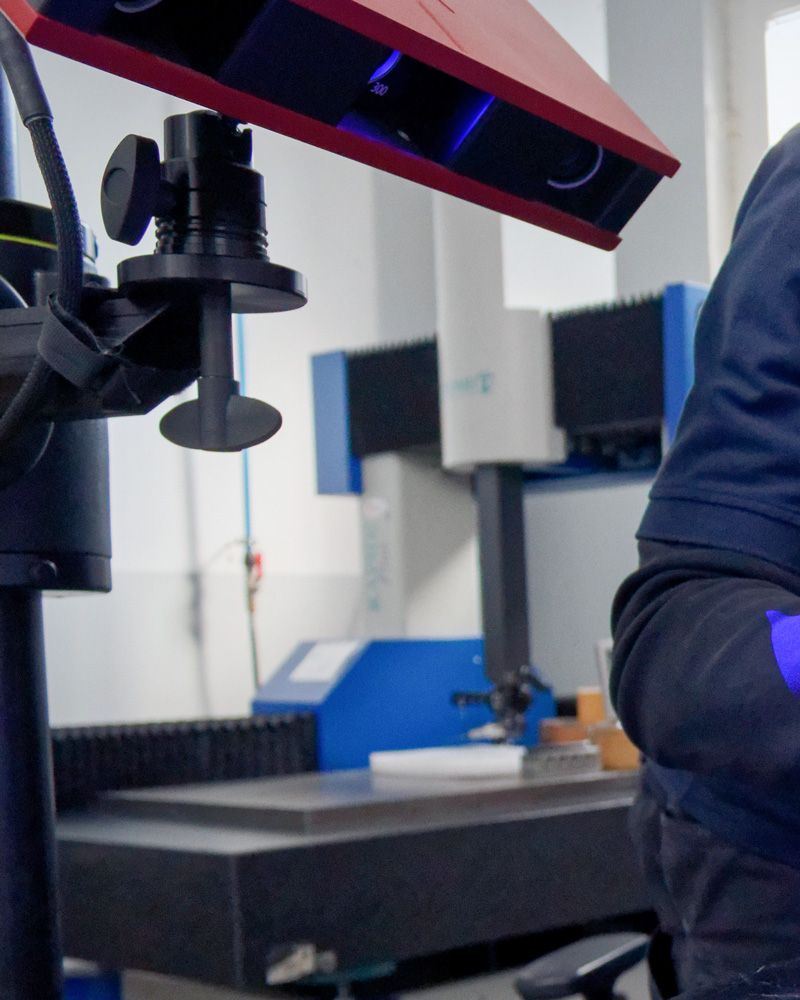

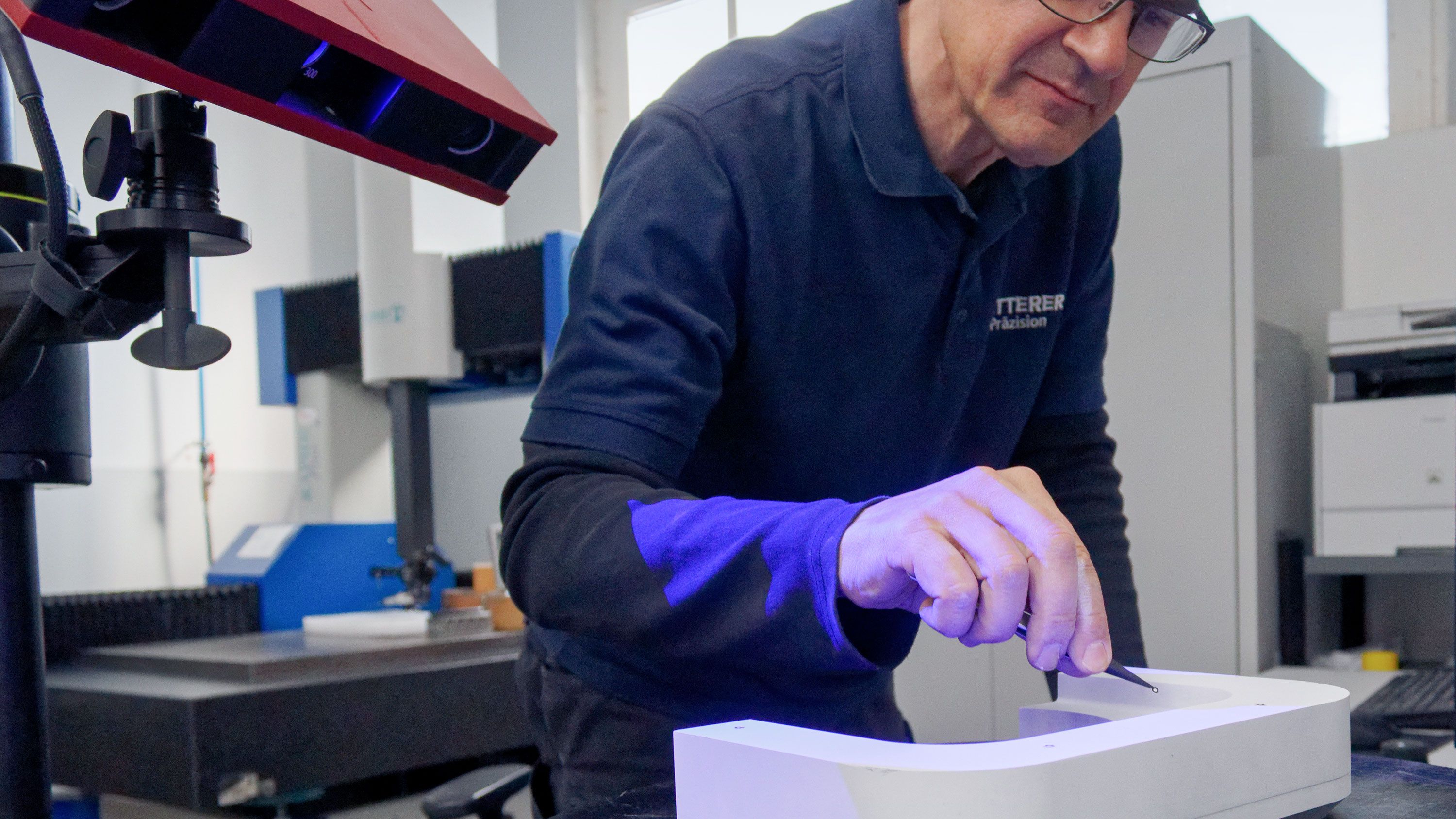

GOM

ZETTERER relies on highly accurate and fast 3D measurement techniques for quality control in the production process. The generated 3D data noticeably reduce post-processing times thanks to the optimized component quality.

- Quality control in the production process

- Reverse engineering

- Components up to 500 millimeters

Mail:

Contact Person:

Alexander Zetterer