Problem

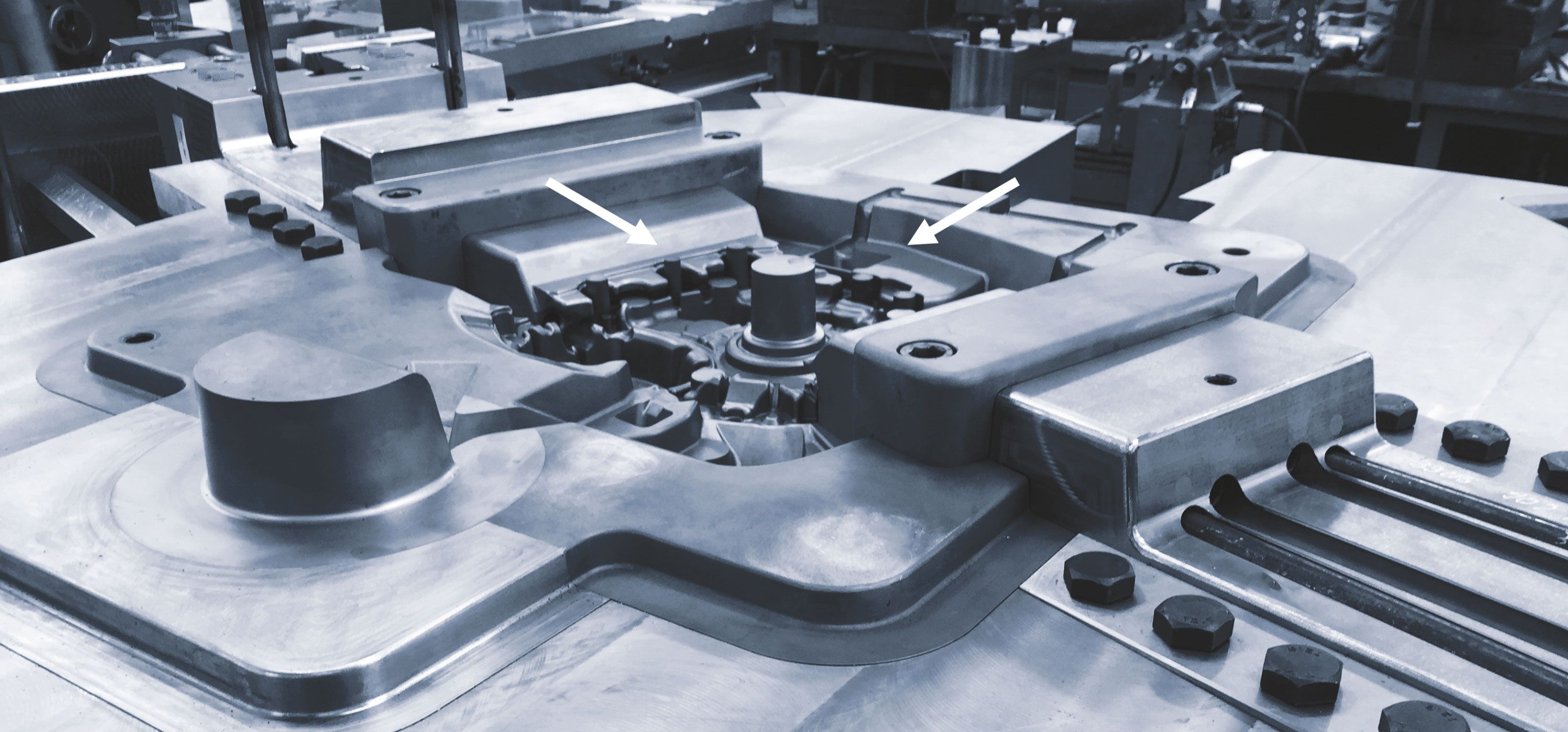

When spraying with spray bars, release agent may not be applied to parts of the mold, especially the undersides of slide surfaces and cores. This can cause aluminum melt to stick. It can also have negative effects on the temperature profile at the mold contour.

Effects

Generally, this leads to problems in quality, as well a greater number of rejected cast parts. This means an increased workload due to more frequent maintenance work being required on the die casting mold.

Due to the high level of wear, there is increased financial outlay for the additional spare parts required. The resulting machine downtime leads to increased costs and possible bottlenecks in delivery to the customer.

How to solve the problem

The implementation of a process-reliable spraying technology for the above-mentioned areas. This is achieved by using different spray nozzles and/or

complete systems from different suppliers, taking into account existing technology.

Solutions following connection to existing spray system of the die casting machine

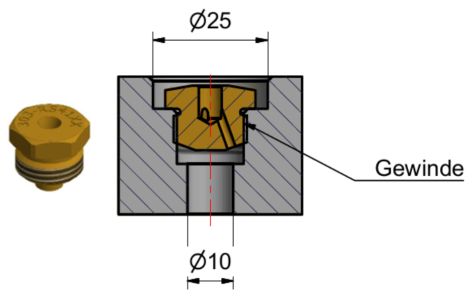

Spray nozzle

Spray nozzle with air and coolant connection, controlled and supplied via machine-side spray unit.

Spray medium supplied through piping

Spray medium supplied through drilled channels

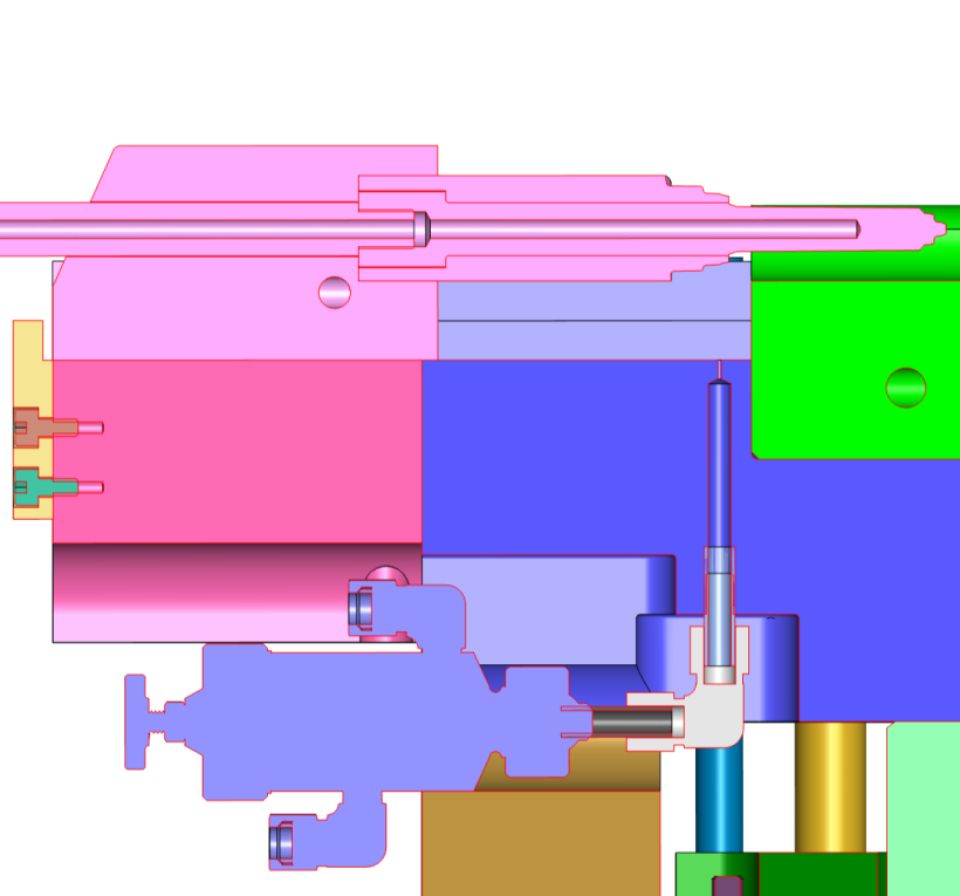

Solution in the form of a complete system

Individual spray patterns are possible by using

the different nozzles of the system. The valve

gate prevents the nozzle opening from sticking, thus increasing process reliability. The option of connecting several nozzles in parallel makes it possible to cover larger mold sections.

spray nozzle with valve gate and complete system with pressure vessel

- option of expanding to max. 4 circuits

- Control by means of 24V connection via machine-side spray unit

Sprühdüse mit Nadelverschluss und Komplettsystem mit Druckbehälter

- Optional für bis zu 4 Kreisläufe erweiterbar.

- Ansteuerung durch 24V-Anschluss über maschinenseitige Sprüheinheit.

Sprühdüse mit Nadelverschluss und Komplettsystem mit Druckbehälter

- Optional für bis zu 4 Kreisläufe erweiterbar.

- Ansteuerung durch 24V-Anschluss über maschinenseitige Sprüheinheit.