Problem definition

Problem solution

The solution to this is Zetterer Retrofit, a measure to modernize or adapt these components. Older components are overhauled or repaired in order to improve their performance, precision and durability. Zetterer Retrofit makes it possible to bring existing components up to the current state of the art in a cost-effective and timely manner instead of replacing them completely.

For example, Zetterer Retrofit can restore the guidance of a slide valve in 2-5 hours for around €500. In contrast, the production of a new gate valve takes 25 hours and requires material and hardening costs of €3500.

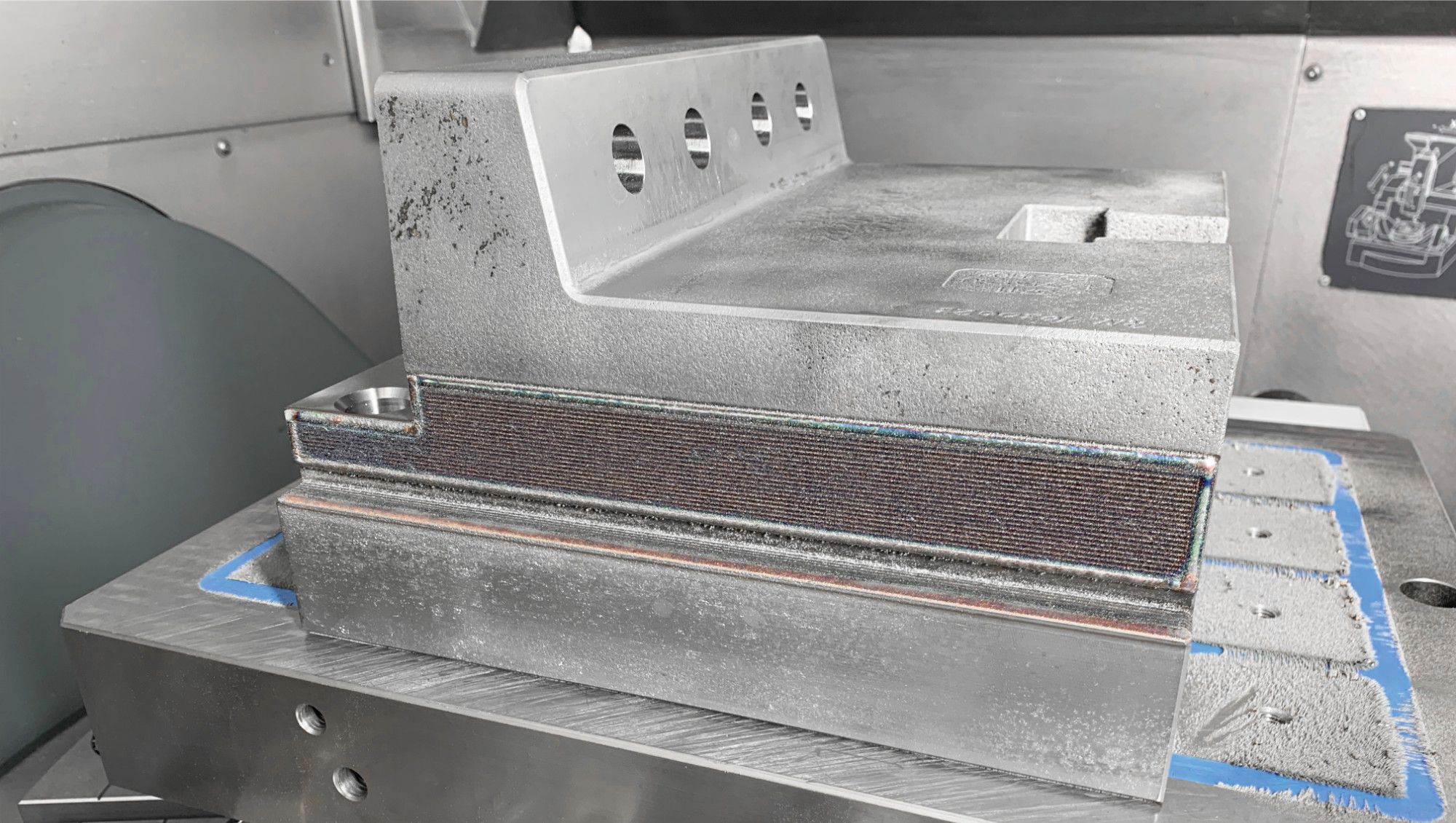

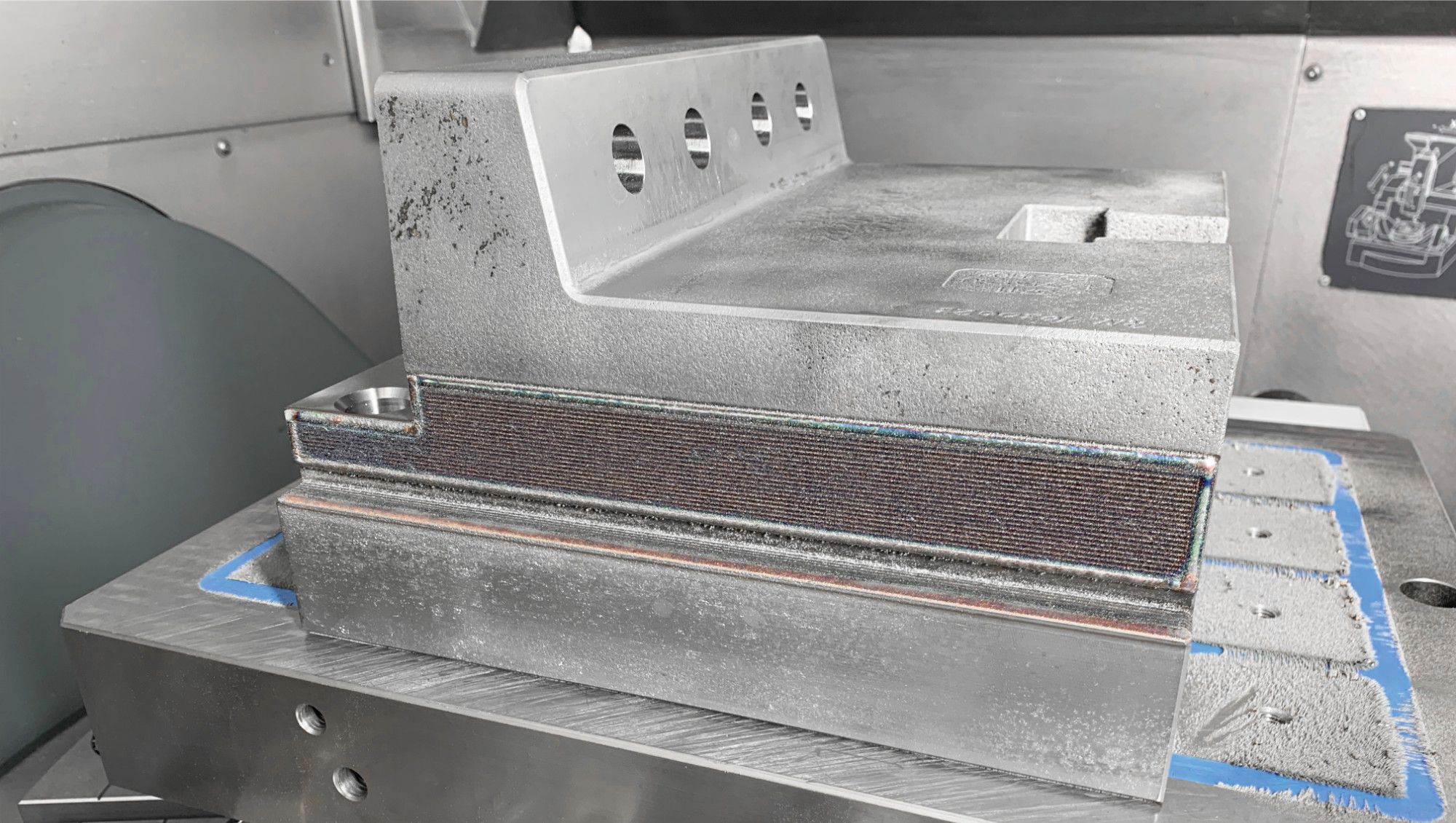

The old components are first milled over, then welded and then milled back to the required dimensions.

What is

Zetterer

Retrofit?

Zetterer Retrofit bezeichnet die Zetterer Retrofit refers to the updating or retrofitting of existing components. Zetterer Retrofit brings them up to the current state of the art.

It is often more cost-effective to modernize older components instead of buying new ones. The goals of Zetterer Retrofit are usually improved efficiency, higher product quality or an extended service life.

Advantages of

Zetterer Retrofit

-

Cost savings compared to a new purchase

-

Employees retain their usual way of working

-

No additional spare parts required

-

Increased productivity and product quality

-

Reduction in production costs

-

Extending the service life of components

In 4 steps to the

“new” component

Analysis of the component

Milling over

Welding

Restoring the dimensions

-

Step 1

Step 1Analysis of the component

The component is checked for wear, damage or performance problems. -

Milling over

Milling overSchweißen

Damaged or inaccurate parts are removed to make room for repairs. -

Step 3

Step 3Welding

Carrying out repairs or modifications to the overmilled components. -

Step 4

Step 4Restoring the dimensions

The repaired components are milled to the required dimensions to ensure accuracy.

brochure free of charge

Do you have

any questions?

-

This email address is being protected from spambots. You need JavaScript enabled to view it.