We offer

two proceedings

Wir bieten zwei Verfahren an

SLM

DED hybrid

Selective Laser Melting

Additive manufacturing by selective laser melting (SLM) in the powder bed.

In selective laser melting, metal powder is deposited in a thin layer on a base plate and then remelted by laser radiation under inert gas.

A solid layer of material is formed. The base plate is then lowered by the amount of a layer thickness and powder is applied again.

| max. X-axis | 250 mm |

| max. Y-axis | 250 mm |

| max. Z-axis | 300 mm |

| Standard Laserpower | 400 W |

| max. Workpiece weight | 200 kg |

Advantages

- Highly complex components with function integration

- Internal, near-contour cooling channels

- Weight reduction through grid and honeycomb structures

- Simultaneous assembly of different workpieces

- Shortened development times due to immediately available metal prototypes

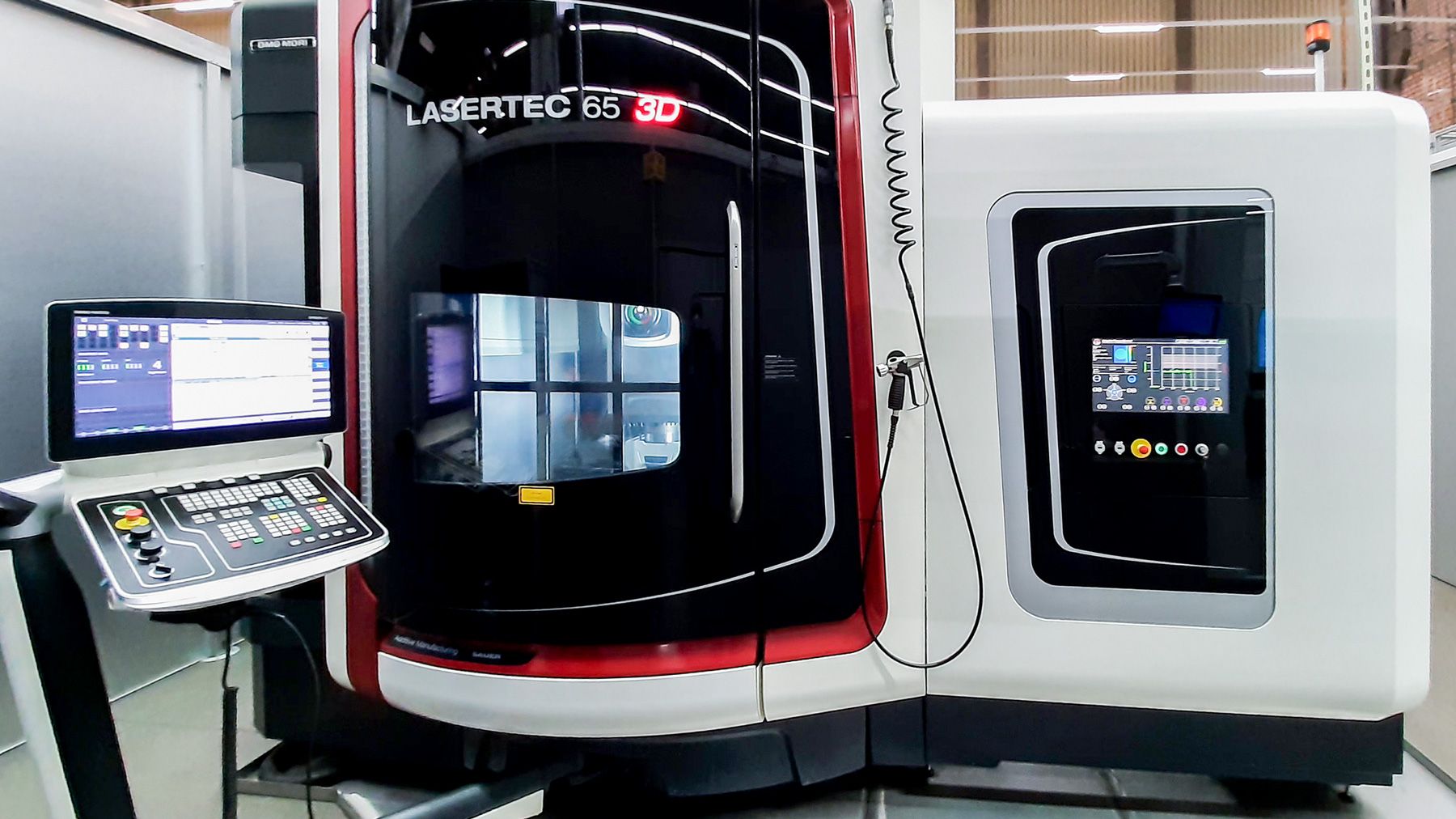

DED hybrid

DED hybrid

Directed Energy Deposition

Additive manufacturing by Directed Energy Deposition (DED) with coaxial powder nozzle, combined with 5-axis milling and turning.

In the DED process, the metal powder is transported with inert gas through a nozzle, where it is melted by a laser and deposited sequentially.

In hybrid complete machining, the DED process is complemented by subsequent machining with milling and turning on the same machine.

| max. X-axis | 735 mm |

| max. Y-axis | 650 mm |

| max. Z-axis | 560 mm |

| Standard Laserpower | 3.000 W |

| max. Workpiece weight | 600 kg |

Advantages

- 5-axis controlled powder buildup welding on complete machining centers enables completely new innovation

- New component geometries through alternating generative and machining processes

- Increased performance through material bonded composites (e.g. steel + copper)

- Fast and cost-effective repair of existing components through hybrid manufacturing methods.

| max. X-axis | 735 mm |

| max. Y-axis | 650 mm |

| max. Z-axis | 560 mm |

| Standard Laserpower | 3.000 W |

| max. Workpiece weight | 600 kg |

Advantages

- 5-axis controlled powder buildup welding on complete machining centers enables completely new innovation

- New component geometries through alternating generative and machining processes

- Increased performance through material bonded composites (e.g. steel + copper)

- Fast and cost-effective repair of existing components through hybrid manufacturing methods.